Automation has revolutionized numerous industries, and the field of box packaging is no exception. The integration of automated systems in packaging processes has significantly improved efficiency, reduced costs, and enhanced the overall quality of packaged products.

What is Automated Box Packaging?

Automated box packaging refers to the use of machines and technologies to perform tasks related to boxing and packaging products. These tasks include filling, sealing, labeling, and sorting, all done with minimal human intervention.

Benefits of Automated Box Packaging

- Increased Efficiency

Automated systems can work continuously without the need for breaks, significantly increasing production output. Machines can handle a high volume of packages in a short period, reducing the time required for packaging tasks.

- Cost Reduction

By automating packaging processes, companies can reduce labor costs and minimize waste. Automated systems often have features that optimize the use of materials, ensuring that every box and label is used efficiently.

- Improved Accuracy

Automated packaging machines are designed to perform tasks with precision. This reduces the likelihood of errors, such as mislabeled packages or improperly sealed boxes. The accuracy of automated systems ensures that products reach consumers in perfect condition.

- Enhanced Safety

Automated packaging processes reduce the need for human workers to handle hazardous materials or perform repetitive tasks that can lead to injuries. This creates a safer work environment for employees and reduces the risk of accidents.

How Automated Box Packaging Works

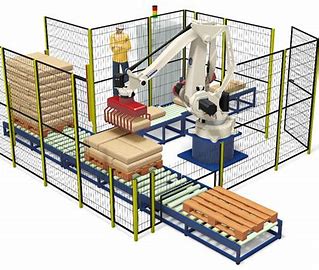

Automated box packaging systems typically consist of several components, including conveyors, feeders, robots, and sensors. Here’s a brief overview of how these components work together:

- Conveyors

Conveyors transport products through the packaging line. They ensure that products are moved smoothly and efficiently from one station to another.

- Feeders

Feeders are devices that supply products to the packaging machines. They ensure that the right number of products are fed into the machine at the right time.

- Robots

Robots are the core of automated packaging systems. They perform tasks such as filling boxes, sealing them, applying labels, and sorting packages. Robots are programmed to work accurately and efficiently, reducing the need for human intervention.

- Sensors

Sensors monitor the packaging process and ensure that everything is working correctly. They detect any issues, such as misaligned boxes or missing labels, and alert the system to take corrective action.

Applications of Automated Box Packaging

Automated box packaging is used in a wide range of industries, including:

- E-commerce

Online retailers rely on automated packaging systems to handle the high volume of orders they receive daily. These systems ensure that orders are packed quickly and accurately, reducing shipping delays and customer complaints.

- Food and Beverage

Automated packaging is essential in the food and beverage industry. It ensures that products are packed in a hygienic and safe manner, reducing the risk of contamination.

- Pharmaceuticals

Pharmaceutical companies use automated packaging systems to ensure that medications are packed correctly and labeled accurately. This reduces the risk of medication errors and ensures that patients receive the correct dosage.

Challenges and Future Trends

While automated box packaging offers numerous benefits, there are also some challenges associated with its use. These include the high initial cost of equipment, the need for ongoing maintenance, and the potential for technical failures.

Despite these challenges, the future of automated packaging looks promising. Advances in technology, such as artificial intelligence and machine learning, are enabling machines to become more intelligent and adaptable. This will lead to even greater efficiency and accuracy in packaging processes.

In conclusion, automated box packaging is a valuable technology that is transforming the way products are packaged and shipped. By increasing efficiency, reducing costs, and improving accuracy, automated systems are helping companies stay competitive in today’s fast-paced market.